Welcome to Jining Yizhan International Trade Co., Ltd

Unlock the Secrets of Cost Reduction and Efficiency Improvement in Small Excavator Operations

I. Optimization of Operational Techniques

Professional Training

Train operators in efficient movements (compound actions, precise rotation) to reduce non-productive operation time

Practice "dig-load-unload" continuity to minimize bucket adjustment frequency

Path Planning

Pre-plan excavation paths to avoid repetitive movement or rotation

Implement "fan-shaped excavation" or "layered excavation" methods to reduce mechanical displacement

Posture Control

Adjust excavator posture (slope angle, depth) according to working conditions to maintain stability and reduce energy consumption

II. Equipment Maintenance & Condition Management

Regular Maintenance

Timely replace hydraulic oil/filters, clean radiators to ensure hydraulic system efficiency

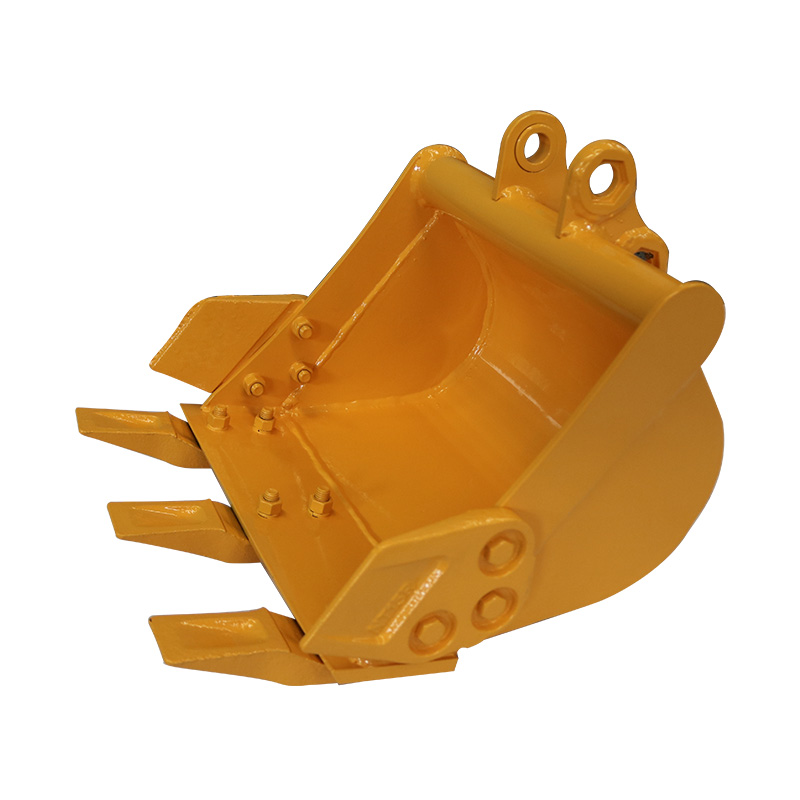

Inspect and replace wear parts (bucket teeth, tracks, cylinder seals)

Power System Optimization

Maintain engine RPM in economical range, avoid prolonged overload

Use low-viscosity oil (winter) / high-viscosity oil (summer) per temperature requirements

Preheating & Cooling

Complete preheating during cold starts; monitor cooling in high-temperature environments

III. Workflow Planning & Optimization

Site Preparation

Clear obstacles and mark work zones to minimize operational pauses

Optimize material stacking to reduce transport distance

Collaborative Operations

Coordinate with dump trucks/loaders using "one truck-three buckets" principle

Implement real-time communication via radios/smart devices

Task Prioritization

Batch similar tasks (complete all excavation before switching to breaking) to reduce attachment changes

IV. Technical Upgrades & Attachment Optimization

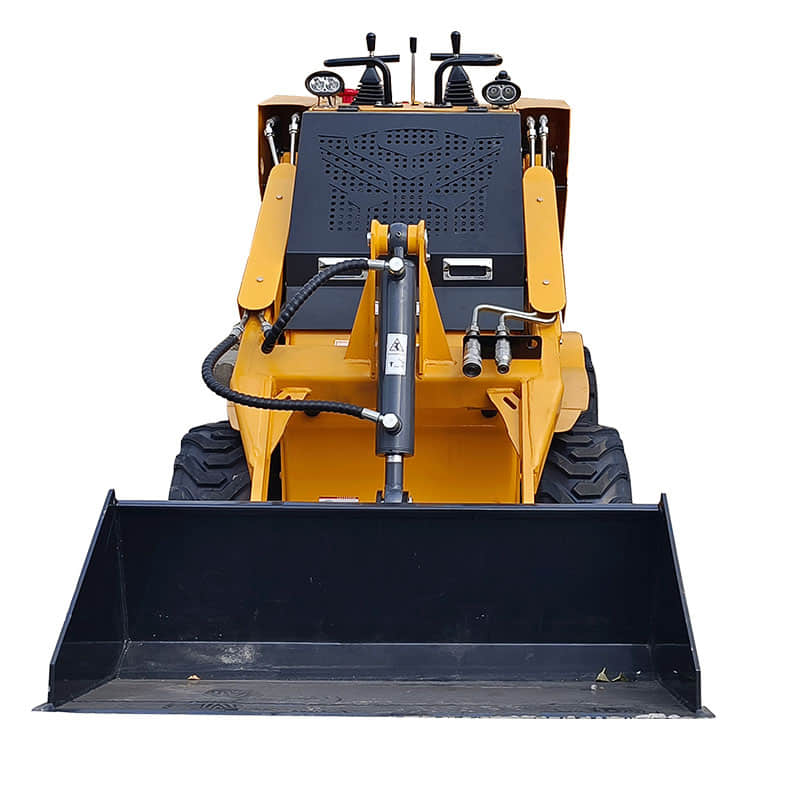

Attachment Compatibility

Select optimal attachments (rock buckets, wide-opening buckets) per task requirements

Implement quick couplers for fast attachment changes

Power Upgrades

Consider electric/hybrid models for fixed-site operations to reduce energy cost