Welcome to Jining Yizhan International Trade Co., Ltd

Do you know what a hydraulic grab for a compact excavator is?

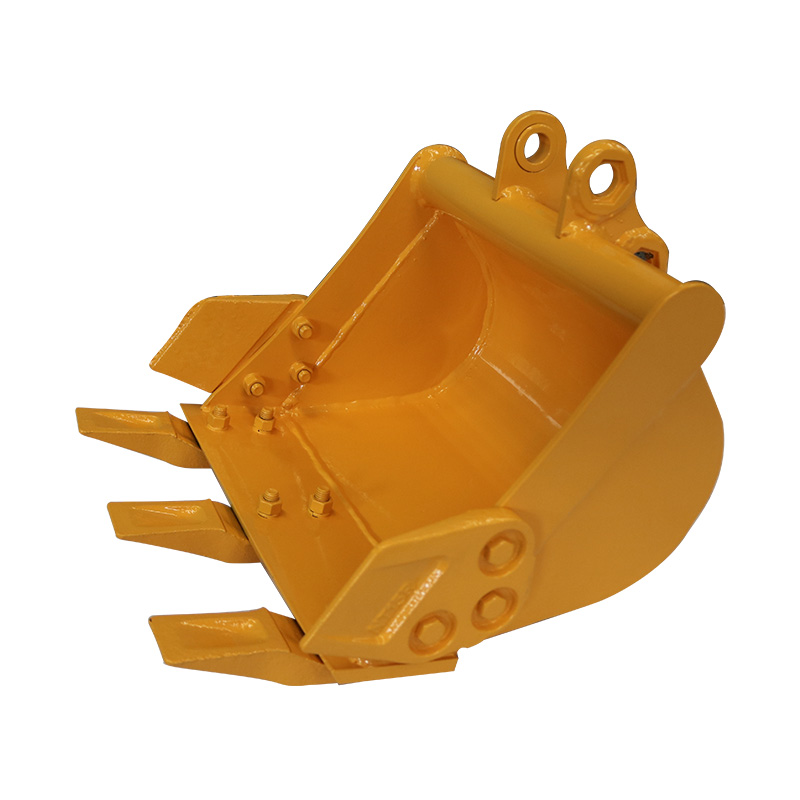

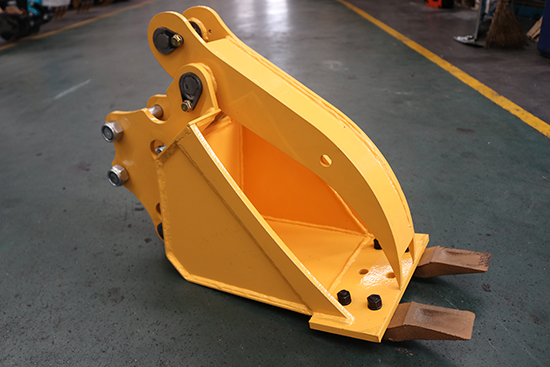

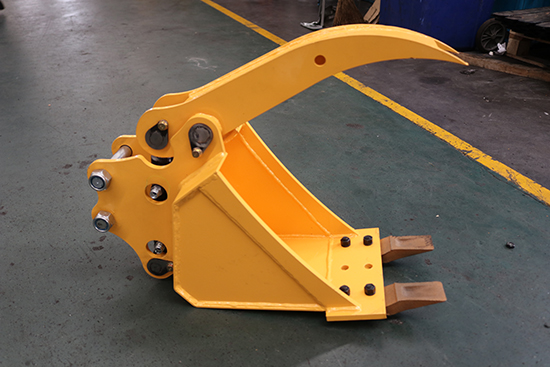

Integrated Hydraulic Thumb (One-piece Hydraulic Thumb)

An Integrated Hydraulic Thumb is an attachment designed for compact excavators that combines the functions of a hydraulic thumb and a traditional bucket. It is mounted directly on the excavator's bucket and enhances the machine's ability to handle, grip, and move materials in a variety of tasks, especially for irregular or loose materials. The thumb is typically operated by the excavator's hydraulic system, allowing for precise control of the gripping action.

Structure and Function of an Integrated Hydraulic Thumb:

Integrated Design: As the name suggests, the "integrated" design refers to the hydraulic thumb being built directly into the excavator's bucket. Unlike separate attachments that need to be swapped out, the hydraulic thumb is permanently attached to the bucket, saving time and effort during operations.

Hydraulic Operation: The hydraulic thumb is powered by the excavator's hydraulic system. Hydraulic fluid flows through the system to hydraulic cylinders that control the opening and closing of the thumb, allowing it to grasp, hold, and release materials with great precision.

Thumb Structure: The hydraulic thumb typically features one or two "thumb-like" components that can move independently or together to grab objects. These thumbs allow the excavator to pick up, hold, and manipulate irregularly shaped or difficult-to-handle materials, such as logs, rocks, debris, or large pipes.

Key Features of the Integrated Hydraulic Thumb:

Efficiency: Compared to traditional buckets, the hydraulic thumb allows for more efficient handling of materials. It provides enhanced precision and grip, especially for materials that are loose, bulky, or oddly shaped, which can be difficult for a regular bucket to handle.

Flexibility: The hydraulic thumb's flexible design allows the excavator to grip and manipulate a wide variety of materials with ease, offering greater versatility for different job types. This feature is particularly useful for handling construction debris, scrap, or tree trunks in tight spaces.

Integrated Design: The thumb is attached directly to the bucket, meaning operators don’t have to swap out attachments during the job. This reduces downtime, simplifies operations, and helps maintain consistent performance throughout the project.

Increased Productivity: By eliminating the need for frequent attachment changes and enabling precise material handling, the integrated hydraulic thumb helps increase overall worksite productivity, making it ideal for jobs like demolition, landscaping, and material sorting.

Common Applications:

Demolition & Debris Removal: The hydraulic thumb is particularly useful for handling and moving construction debris, scrap metal, large rocks, and other loose materials during demolition or site cleanup.

Landscaping & Tree Removal: In landscaping, the thumb is excellent for moving trees, branches, stumps, or large rocks that would be difficult for a standard bucket to handle.

Construction Sites: Ideal for moving irregularly shaped construction materials such as steel beams, pipes, and stone blocks.

Recycling & Waste Management: The hydraulic thumb helps with the efficient handling of scrap materials, like metal, plastic, and wood, during recycling or waste management operations.

Advantages:

No need for frequent attachment changes, saving time and improving workflow.

High adaptability, capable of grabbing a wide variety of materials, from small debris to large, irregularly shaped objects.

Increased precision and control in handling materials, reducing the risk of damage.

Enhanced versatility for small excavators, making them suitable for a broader range of tasks on various job sites.

In summary, the Integrated Hydraulic Thumb is a highly practical attachment for compact excavators. It enhances the machine's ability to perform delicate or complex tasks, such as gripping and transporting irregularly shaped materials, without the need to switch out attachments frequently. This increases operational efficiency, making it a valuable tool for a wide range of industries, from construction to landscaping and waste management.