Welcome to Jining Yizhan International Trade Co., Ltd

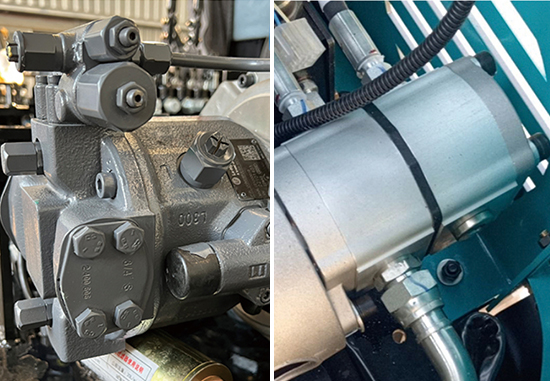

What’s the difference between a piston pump and a gear pump?

Plunger Pumps vs. Gear Pumps: Key Differences

Plunger pumps and gear pumps are two common types of hydraulic pumps, each with distinct operating principles and application scenarios. Below is a comparison:

1. Operating Principle

Plunger Pump:

Generates pressure and flow through the reciprocating motion of plungers.

Driven by a swash plate or cam within the cylinder block.

Often designed as a variable displacement pump, allowing adjustable output.

Gear Pump:

Moves fluid by the rotation of interlocking gears.

Relies on volumetric changes created by the gears rather than plungers.

Typically a fixed displacement pump with constant output.

2. Pressure Capability

Plunger Pump:

Handles higher pressure levels, usually up to 30–50 MPa, ideal for demanding applications.

Gear Pump:

Operates at moderate pressures, generally in the range of 10–25 MPa.

3. Efficiency

Plunger Pump:

Offers higher volumetric and mechanical efficiency.

Performs better in high-pressure environments with minimal energy loss.

Gear Pump:

Lower efficiency, especially at high pressures, due to increased internal leakage.

4. Complexity and Maintenance

Plunger Pump:

Complex structure with higher manufacturing and maintenance costs.

Requires precise seals and components like plungers and distribution plates.

Gear Pump:

Simple design, cost-effective, and highly reliable.

Easy to maintain, making it suitable for budget-conscious systems.

5. Adjustability

Plunger Pump:

Often a variable displacement pump, capable of adjusting flow and pressure based on system requirements.

Suitable for dynamic and varied operating conditions.

Gear Pump:

Typically fixed displacement, with output controlled via external valves if needed.

6. Applications

Plunger Pump:

Used in high-pressure, precision, and variable demand environments like construction machinery (excavators, cranes), aerospace systems, and industrial equipment.

Gear Pump:

Ideal for moderate pressure and fixed flow scenarios, such as agricultural machinery, forklifts, and small industrial systems.

7. Durability and Longevity

Plunger Pump:

Well-suited for continuous high-pressure operations but sensitive to fluid quality.

Higher repair costs if wear occurs.

Gear Pump:

More tolerant of fluid contaminants but generally shorter lifespan.

Easier and cheaper to replace or repair.

Summary Table

| Aspect | Plunger Pump | Gear Pump |

|---|---|---|

| Pressure | High (30–50 MPa) | Moderate (10–25 MPa) |

| Efficiency | High | Lower |

| Design Complexity | Complex | Simple |

| Adjustability | Variable Displacement | Fixed Displacement |

| Application | High precision & high pressure | Moderate cost & pressure |

| Maintenance Cost | High | Low |

Choose the right pump based on your operational needs for optimal performance and cost-effectiveness.