Welcome to Jining Yizhan International Trade Co., Ltd

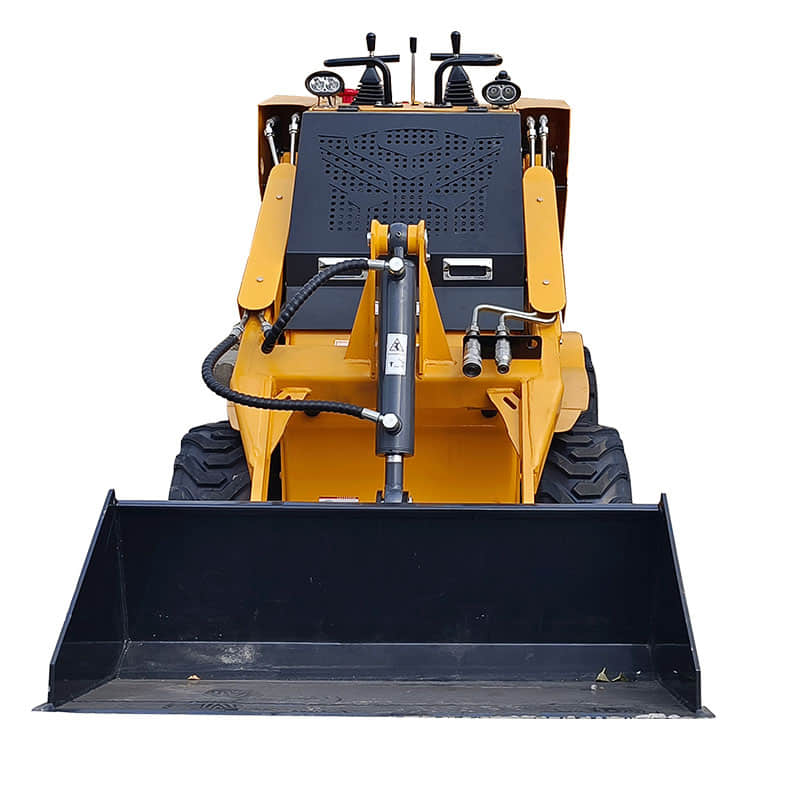

How to Maximize the Performance of a Compact Excavator

To push a compact excavator to its full potential, focus on operational techniques, maintenance, versatility, and planning. Here’s a detailed guide tailored for Western operators and worksites:

1. Master Advanced Operating Techniques

Smooth Control

Avoid jerky lever movements; use gradual inputs to reduce hydraulic stress.

Practice combined motions (e.g., boom, arm, and bucket synchronized) for efficiency.

Terrain Adaptation

Use track pads/mats on soft ground; adjust counterweight positioning on slopes.

Stabilize the machine by lowering the blade or tilting the bucket when working on uneven surfaces.

Smart Digging

Layer-by-layer excavation: Remove material in stages to avoid overloading the bucket.

Utilize the bucket’s side edge for grading or trench cleaning.

2. Rigorous Maintenance Practices

Daily Checks

Inspect hydraulic fluid, coolant, and filters. Clear debris from tracks and undercarriage.

Check for leaks, loose bolts, or worn pins.

Scheduled Servicing

Replace hydraulic oil, engine oil, and filters per manufacturer guidelines (typically every 500 hours).

Lubricate joints (bucket pins, swing bearings) to prevent premature wear.

Proactive Repairs

Address unusual vibrations, noises, or reduced power immediately. Monitor hydraulic hose integrity and cylinder seals.

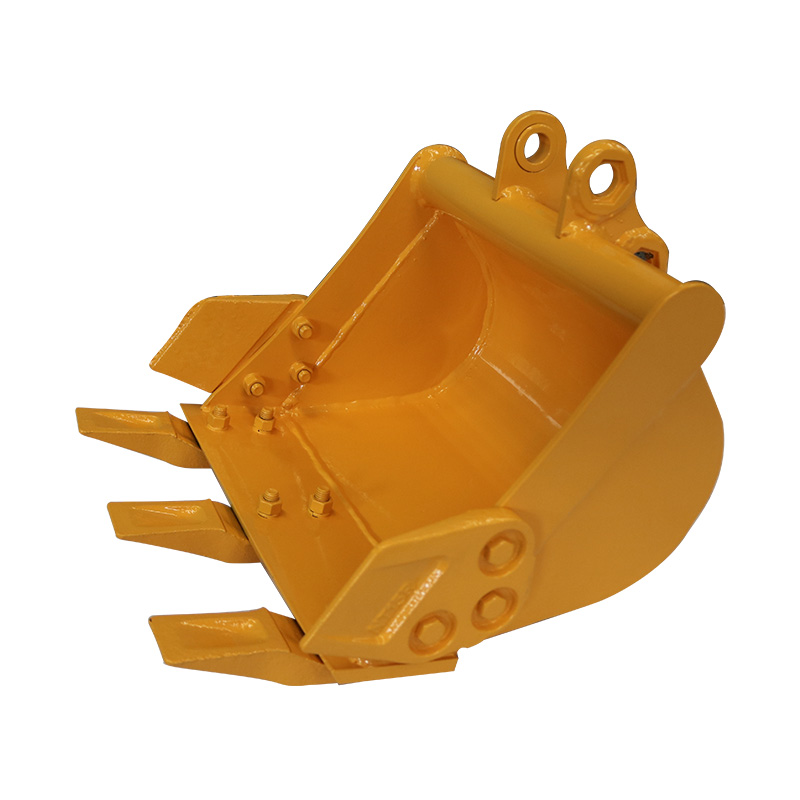

3. Expand Versatility with Attachments

Quick Coupler Compatibility

Hydraulic Breaker: Crush concrete/rock.

Grapple/Clamp: Handle logs, scrap, or pipes.

Auger: Drill holes for fencing or foundations.

Angle Tilt Bucket: Precision grading.

Swap attachments for specialized tasks:

Beyond Digging

Add a lifting eye for light crane work (stay within load limits).

Use a ripper/soil loosener for agricultural or landscaping tasks.

4. Optimize Job Site Efficiency

Plan Strategically

Map out work zones to minimize repositioning.

Group similar tasks (e.g., dig all trenches before backfilling).

Time Management

Avoid prolonged operation in extreme heat to prevent overheating.

Equip LED lights for safe night shifts.

5. Safety & Load Discipline

Respect Capacity Limits

Never force the machine to dig beyond its breakout force.

Keep loads low during transport to maintain stability.

Hazard Awareness

Avoid unstable ground (e.g., one-track悬空).

Locate underground utilities and overhead hazards before digging.

6. Tech Upgrades & Customization

Smart Add-Ons

Install telematics/GPS for real-time monitoring of fuel usage and productivity.

Use wireless remote control for hazardous environments.

Performance Tuning

Switch engine modes (Eco/Power) based on workload.

Upgrade hydraulic flow/pressure (consult OEM guidelines).

7. Operator Training & Team Coordination

Skill Development

Train operators on simulators for complex scenarios.

Teach troubleshooting (e.g., diagnosing hydraulic issues via fluid analysis).

Crew Collaboration

Sync with dump trucks or skid steers to eliminate downtime.

Brief teams on daily goals to streamline workflows.