Welcome to Jining Yizhan International Trade Co., Ltd

- January 22, 2025

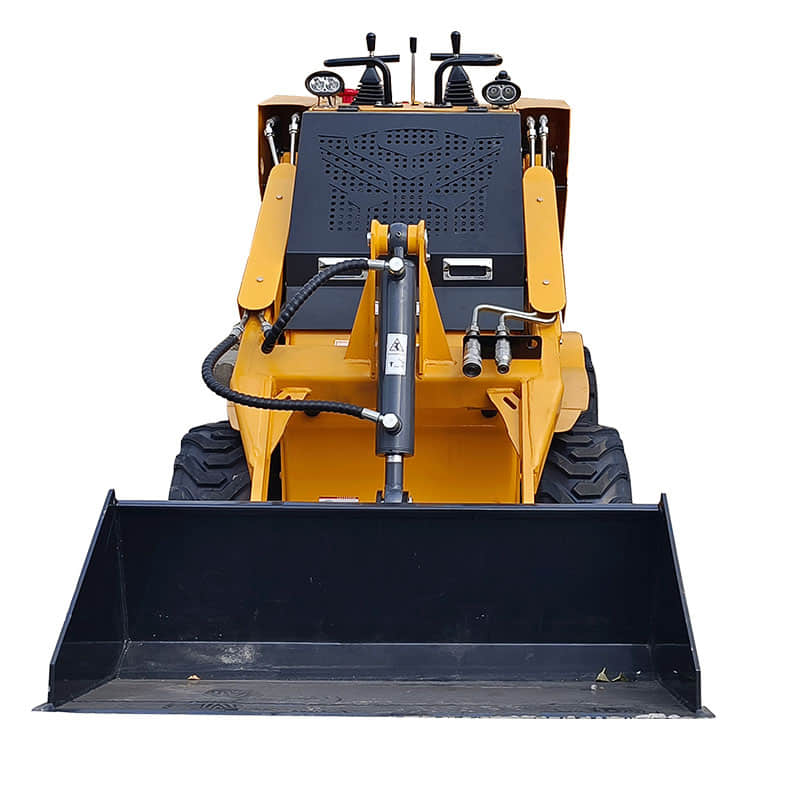

Do you know about the brush cutter on a skid - steer loader?

Definition and Function

The brush cutter on a skid - steer loader is an accessory device mainly used for cutting shrubs, weeds, and some small - sized vegetation. It is powered by the hydraulic system of the skid - steer loader, which drives the cutting components of the brush cutter to rotate, thus efficiently clearing the vegetation in the site. This equipment plays an important role in areas such as landscape maintenance, roadside vegetation clearance, and farm weed removal.

Structural Composition

Connection Device:

The connection device is used to firmly install the brush cutter on the skid - steer loader. This part of the structure must ensure that the brush cutter does not loosen or fall off during operation. Usually, a combination of high - strength bolts and slots is used, which allows for quick installation and disassembly, facilitating the use and maintenance of the equipment.

Transmission System:

It is mainly responsible for transmitting the hydraulic power of the skid - steer loader to the cutting components to make them rotate. The transmission system generally includes parts such as a hydraulic motor and a drive shaft. The hydraulic motor receives power from the hydraulic system of the loader and transfers the power to the cutting components through the drive shaft, ensuring a stable rotation speed.

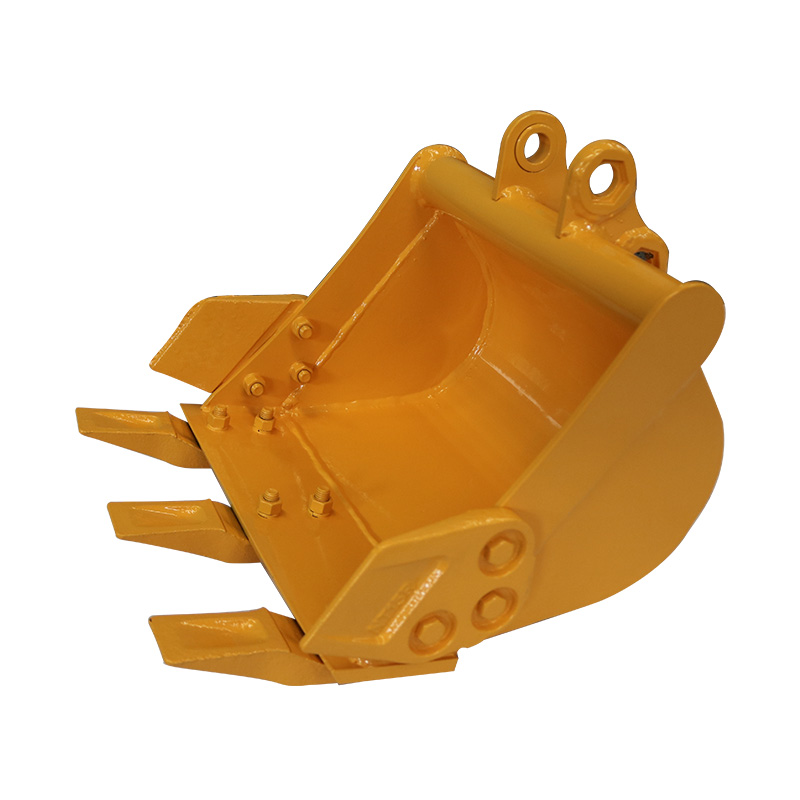

Cutting Components:

The cutting components of the brush cutter usually consist of a set of high - speed rotating blades or nylon ropes. The blades are generally made of high - strength alloy steel with sharp edges, capable of easily cutting through the stems of shrubs and weeds. Nylon ropes are relatively soft and suitable for cutting thinner weeds. They are less likely to cause serious damage when hitting obstacles, providing a slightly higher level of safety.

Working Principle

When the hydraulic system of the skid - steer loader is activated, the hydraulic oil is delivered to the hydraulic motor of the brush cutter. Driven by the hydraulic oil, the hydraulic motor starts to rotate, driving the drive shaft and the cutting components to rotate together. The cutting components come into contact with the vegetation in a high - speed rotation state. Using their kinetic energy and sharp edges (or the whipping action of the rope), the shrubs, weeds, and other vegetation are cut off, thus achieving the purpose of clearing the vegetation.

Advantages

High Efficiency:

Compared with traditional manual tools or small handheld brush cutters, the brush cutter on a skid - steer loader is extremely efficient. It can clear a large area of vegetation in a short time, greatly saving labor and time costs. For example, when clearing weeds in the fields and around the edges of large farms, using this equipment can quickly complete the task and improve the production efficiency of the farm.

Strong Adaptability:

It can be adjusted according to different types and growth conditions of vegetation. By replacing different types of cutting components (such as blades or nylon ropes) or adjusting the rotation speed of the cutting components, it can adapt to the cutting of various vegetation from soft and thin weeds to thick shrubs. At the same time, since it is installed on a skid - steer loader, it can be easily moved and operated in different terrains, such as slopes and rugged wasteland.

High Safety:

The operator can operate the brush cutter from the cab of the skid - steer loader, maintaining a certain safe distance from the cutting components, avoiding the potential harm caused by direct contact with the high - speed rotating blades or nylon ropes. Moreover, when encountering obstacles that are difficult to cut, the operator can promptly control the loader to retreat or adjust the cutting angle, reducing the occurrence of equipment damage and safety accidents.

Precautions for Use

Vegetation Conditions and Environmental Factors:

The cutting height and speed of the brush cutter should be reasonably adjusted according to the height, density, and type of vegetation. In wet environments or under severe weather conditions (such as heavy rain, strong winds, etc.), try to avoid using the brush cutter to avoid affecting the operation effect and increasing safety risks.

Equipment Inspection:

Before use, a comprehensive inspection of the brush cutter should be carried out, including the wear condition of the cutting components, the normal connection of the transmission system, and whether there is any leakage in the hydraulic system. Ensure that the equipment is in good working condition to avoid malfunctions during operation.

Safety Protection:

Although the brush cutter is designed with safety in mind, during operation, the operator should still wear protective equipment, such as a safety helmet, goggles, and protective clothing. At the same time, warning signs should be set up around the work site to prevent unauthorized personnel from entering the operation area.

Operation Training:

The operator needs to undergo professional training, be familiar with the operation methods of the skid - steer loader and the brush cutter, and understand the performance and working range of the equipment. Only by mastering the correct operation skills can the safe and efficient use of the equipment be ensured.

Product Categories

Popular Products

Recent News

Copyright ©2024 All Rights Reserved by Jining Yizhan International Trade Co., Ltd