The hydraulic thumb grip of a small excavator is an accessory device installed on the front working device (such as the boom or bucket) of the excavator. It is shaped like a movable "thumb" and its opening and closing actions are controlled by the hydraulic system.

The hydraulic thumb grip is connected to the excavator's hydraulic system. When the operator manipulates the control lever of the excavator, hydraulic oil is delivered to the hydraulic cylinder of the thumb grip. The pressure of the hydraulic oil pushes the piston to move, thereby opening or closing the gripping arm of the thumb grip. For example, when an object needs to be grasped, the control lever controls the hydraulic oil to enter the corresponding chamber of the hydraulic cylinder, causing the gripping arms of the thumb grip to close and firmly hold the object.

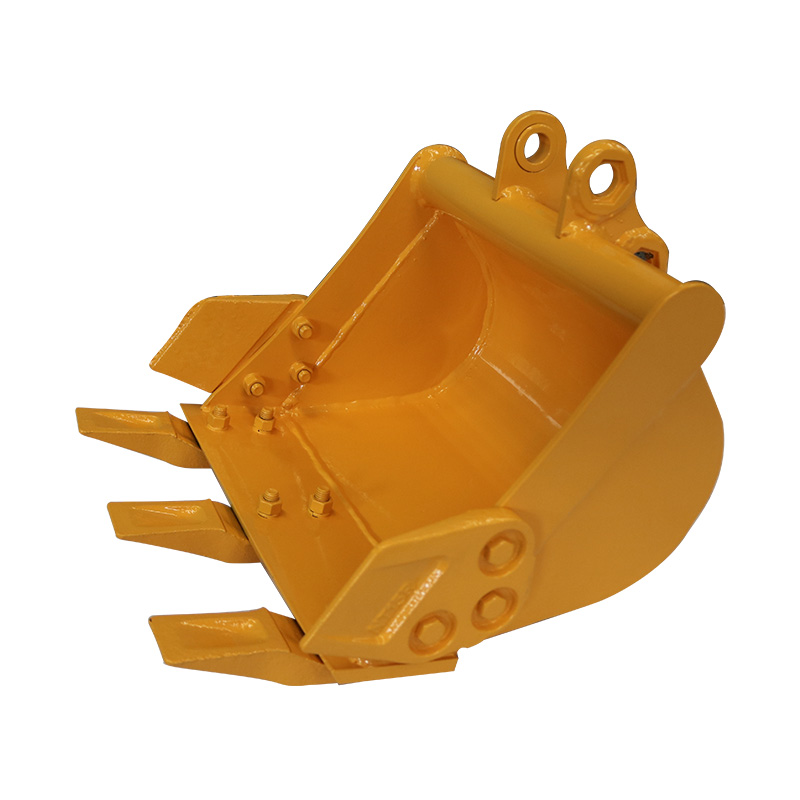

The gripping arm is the part that directly contacts the object being grasped. It is usually made of high-strength steel. Its shape is designed to better fit the surface of the object, increasing the stability of the grip. Some inner sides of the gripping arms are equipped with tooth-like structures. This can prevent the grasped object from slipping, especially when handling materials with relatively smooth surfaces (such as logs, steel pipes, etc.). The tooth-like structures can play a good anti-slip role.

The hydraulic cylinder is the power core of the hydraulic thumb grip. It consists of components such as the cylinder barrel, piston, and piston rod. The cylinder barrel is filled with hydraulic oil. The piston, under the pressure of the hydraulic oil, drives the piston rod to move. The sealing performance of the hydraulic cylinder is crucial. Good sealing can ensure that the hydraulic oil does not leak, thus ensuring the normal operation of the thumb grip. The size and stroke of the hydraulic cylinder vary according to the design purpose and load capacity of the thumb grip.

The connection section is used to install the hydraulic thumb grip on the excavator. It needs to ensure a firm connection between the thumb grip and the working device of the excavator. At the same time, the convenience of installation and disassembly should also be considered. There are various connection methods. A common one is to fix it through bolts and specially designed connection brackets. Moreover, there are buffer devices at the connection parts to reduce the impact generated by the thumb grip on components such as the excavator's boom during the working process.

Grasping Function: It can grasp various objects of different shapes and sizes, such as construction waste (bricks, concrete blocks, etc.), garden waste (branches, tree stumps, etc.), and agricultural materials (hay, agricultural products, etc.).

Auxiliary Handling: When loading and unloading goods, it can be used as an auxiliary tool to help place the goods accurately in the designated position. For example, when transporting building materials from a transport vehicle to a designated storage point at a construction site, the hydraulic thumb grip can precisely control the placement position of the materials.

Construction Industry: It is used to clean up debris at construction sites and transport small building materials. For example, during interior decoration, it can be used to transport tiles, small stones, and other materials. It can also clean up construction waste after wall demolition.

Landscaping Industry: It plays an important role in the construction and maintenance of landscape gardens. It can be used to transplant trees and grasp and transport landscape stones. For example, when planting large landscape trees, the hydraulic thumb grip can easily move the tree balls or saplings with soil balls into the planting pits.

Agricultural Field: It is used for material handling on farms, such as stacking hay and transporting agricultural products. For example, during the harvest season, it can be used to move bundled crops onto transport vehicles, improving labor efficiency.

Improved Work Efficiency: Compared with manual handling or using simple tools, the hydraulic thumb grip can quickly grasp and move objects, greatly reducing working time. For example, when dealing with construction waste, the hydraulic thumb grip can clean up a large amount of waste in a short time, accelerating the cleaning speed of the construction site.

Enhanced Operational Flexibility: It can perform grasping operations at different angles and positions, adapting to various complex working environments. Small excavators themselves have good mobility. With the hydraulic thumb grip, they can complete material handling and cleaning tasks in narrow spaces (such as in the narrow alleys of urban building demolition sites, narrow passages in gardens, etc.).

Versatility: By replacing different types of thumb grips or adjusting their working parameters, it can adapt to a variety of different tasks. For example, changing the shape of the gripping arm or increasing its length can be used to grasp objects of different shapes and sizes.

Limited Load Capacity: Due to the power and structural limitations of small excavators themselves, the load capacity of the hydraulic thumb grip is relatively small. Generally, it is suitable for grasping relatively light objects. For overly heavy large objects, it may not be able to grasp them effectively. Otherwise, it will cause damage to the hydraulic system and working device of the excavator.

High Cost: The purchase and installation of a hydraulic thumb grip require certain costs, including the price of the equipment itself, installation and commissioning costs, etc. Moreover, the maintenance and repair of the hydraulic thumb grip also require a certain cost, such as regularly replacing hydraulic oil and repairing hydraulic cylinders.