What should be done if the speed of a small - sized excavator is lost? By doing this, it can be easily solved.

If the speed of a small - sized excavator is lost, the following aspects can be checked and solved:

Fuel System

Problems with the injectors will lead to incomplete fuel combustion and affect engine power.

Use professional equipment to check the injection status of the injectors. If there is a fault, they can be cleaned or replaced.

A clogged fuel filter will limit the fuel supply. Generally, the fuel filter of a small - sized excavator needs to be checked every 200 - 300 working hours.

If it is found to be clogged, replace it promptly.

Intake System

A dirty air filter will reduce the amount of air entering the engine, causing an imbalance in the fuel - air mixture ratio.

The air filter generally needs to be checked every 100 - 200 working hours and cleaned or replaced if necessary.

Clogged Air Filter:

Air Intake Pipe Leakage:

Hydraulic Oil Problems

The hydraulic oil will become contaminated after long - term use, affecting the performance of the system.

Generally, the hydraulic oil needs to be replaced every 1500 - 2000 working hours, and the hydraulic oil filter should be replaced at the same time.

Faults of Hydraulic Pump and Hydraulic Motor

A faulty hydraulic motor will also affect the speed of the excavator's movements.

Check whether the hydraulic motor has leakage, abnormal noise, and other issues. If it is damaged, replace it promptly.

Wear or damage to the hydraulic pump will result in insufficient hydraulic oil pressure.

Professionals can use testing equipment to check the hydraulic pump. If there is a fault, it needs to be repaired or replaced.

Hydraulic Pump Fault:

Hydraulic Motor Fault:

Track or Tire Problems

For tire - mounted excavators, insufficient tire pressure will increase the driving resistance.

Regularly check the tire pressure and inflate it according to the specified value.

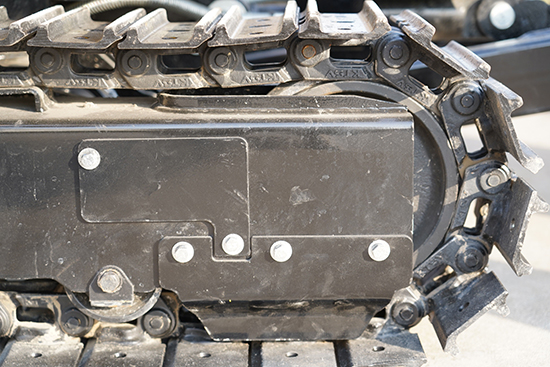

Tracks that are too loose or too tight will affect the speed of the excavator.

Generally, the track sag should be maintained at 30 - 50 mm, which can be achieved by adjusting the tensioning device.

Track Tension:

Tire Pressure:

Loose Transmission Chains or Belts:

Transmission Faults:

Gear wear, clutch slippage, and other issues inside the transmission will lead to poor power transmission.

Check the transmission oil level and quality. If the oil changes color or has an abnormal smell, replace it promptly. For serious faults, professional maintenance is required.

Loose Wire Connections:

Check whether the wire connections in all parts of the excavator are firm and whether there are any loose or oxidized conditions.

If loose connections are found, reconnect and tighten them. If there is oxidation, clean them before reconnecting.

Sensor Faults:

Faults of speed sensors, pressure sensors, etc. will affect the information obtained by the engine control unit.

Use professional diagnostic equipment to test the sensors and replace them if there is a fault.

Controller Faults:

A faulty controller of the excavator will lead to abnormal speed.

Professional personnel are required to test and repair it, and replace the controller if necessary.

By systematically checking the above - mentioned key systems, it is easier to identify the cause of the speed loss of a small - sized excavator and solve the problem.