Welcome to Jining Yizhan International Trade Co., Ltd

- April 23, 2025

How can mini excavators reduce construction costs?

-

Improve Equipment Utilization Rate

-

Optimize Construction Plans: Plan the construction process and sequence in advance to ensure that the work arrangements of the excavators are compact and minimize idle time. For example, before the excavation work, arrange the deployment of transport vehicles in advance so that the excavated soil can be transported away in a timely manner, avoiding the shutdown of the excavator due to waiting for transportation.

-

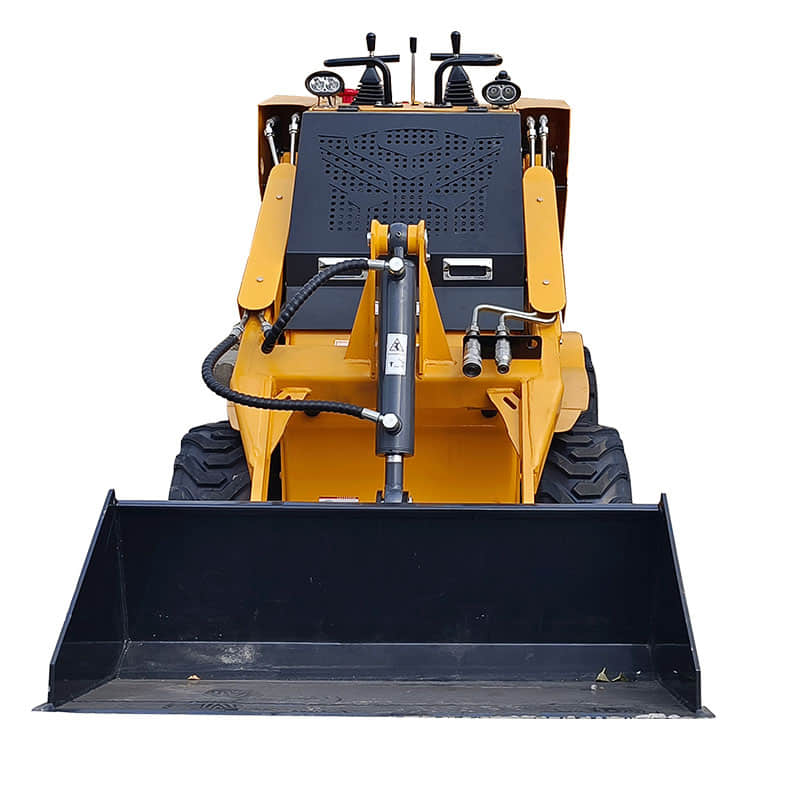

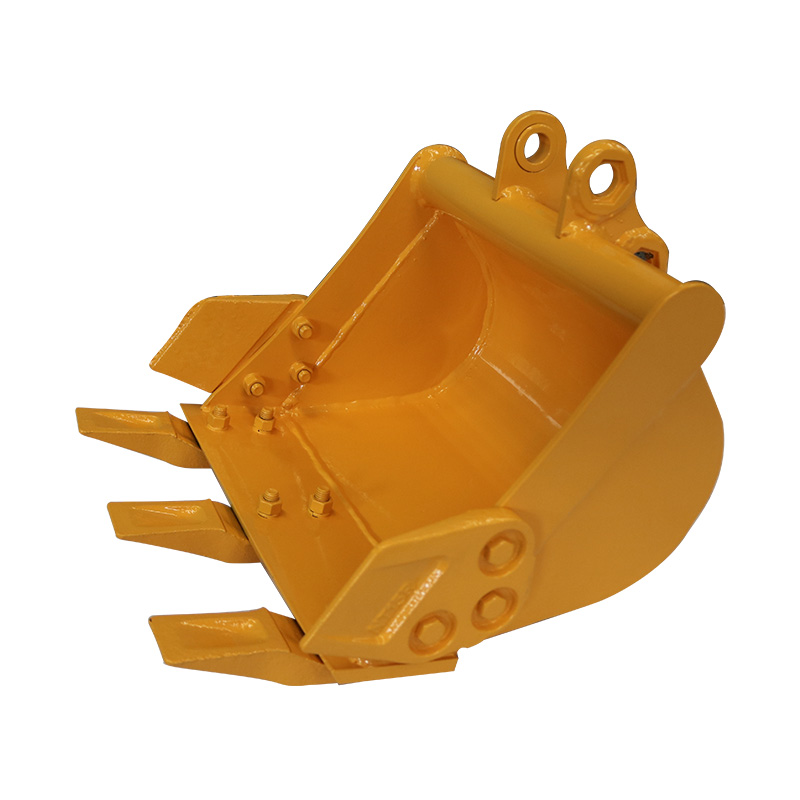

Multi - purpose Use: Give full play to the versatility of mini excavators. In addition to basic excavation operations, different attachments such as breaker hammers, grabs, and rippers can be equipped to complete various tasks such as breaking, grabbing, and loosening soil, reducing the cost of renting other equipment.

-

Reduce Fuel Consumption

-

Reasonably Select Working Modes: Select appropriate engine working modes according to the actual workload. For example, use the economic mode for light - load operations to reduce fuel consumption; use the power mode for heavy - load operations to ensure work efficiency, but avoid running in a high - fuel - consumption mode for a long time.

-

Maintain Good Operating Habits: Avoid sudden acceleration, sudden braking, and long - term idling. During the excavation process, try to maintain uniform driving and smooth excavation movements to reduce unnecessary fuel waste.

-

Regular Equipment Maintenance: Keep the engine, hydraulic system, and other components of the excavator in good working condition. Regularly replace air filters, fuel filters, etc., to improve fuel combustion efficiency and reduce fuel consumption.

-

Reduce Maintenance Costs

-

Regular Maintenance: Develop a detailed maintenance plan according to the requirements of the equipment manufacturer. Regularly maintain the excavator, including changing engine oil, hydraulic oil, filters, and checking and adjusting the clearances of various components. Timely detect and address potential fault hazards to prevent minor problems from developing into major failures, thereby reducing maintenance costs.

-

Operate the Equipment Correctly: Operators should strictly follow the operating procedures to avoid equipment damage caused by improper operation. For example, during excavation, avoid over - excavation or forcibly excavating hard objects to prevent damage to the bucket and hydraulic system; when driving, pay attention to avoiding obstacles to prevent damage caused by collisions.

-

Use High - Quality Spare Parts: When maintaining and repairing, use reliable original spare parts or certified high - quality alternatives. Although high - quality spare parts may be more expensive, they have a longer service life, which can reduce the number of maintenance times and downtime caused by spare - part failures. In the long run, this helps to reduce costs.

-

Optimize Labor Costs

-

Improve Operator Skills: Regularly train operators to improve their operating skills and efficiency, enabling them to master various operating techniques of the excavator proficiently and complete more work in the shortest possible time, thereby reducing the labor cost per unit of work.

-

Reasonably Arrange Staffing: Arrange the number of operators reasonably according to the size and complexity of the construction task to avoid redundant personnel. While ensuring the construction progress, try to minimize unnecessary labor cost expenditures.

-

Other Measures

-

Select Appropriate Equipment: When purchasing or leasing mini excavators, select equipment with reliable performance and high cost - effectiveness according to the actual construction needs. Do not blindly pursue high - end equipment to avoid unnecessary purchase or lease costs. At the same time, consider the versatility and compatibility of the equipment to enable flexible use in different construction projects.

-

Do a Good Job in Equipment Management: Establish equipment files to record the use, maintenance, repair, and other situations of the equipment, so as to timely grasp the operating status of the equipment and provide a basis for equipment renewal, maintenance, and repair. At the same time, strengthen the safety management of the equipment to prevent the equipment from being stolen or causing safety accidents, avoiding the resulting economic losses.

Product Categories

Popular Products

Recent News

Copyright ©2024 All Rights Reserved by Jining Yizhan International Trade Co., Ltd